Our target industries are additive manufacturing and the battery industry

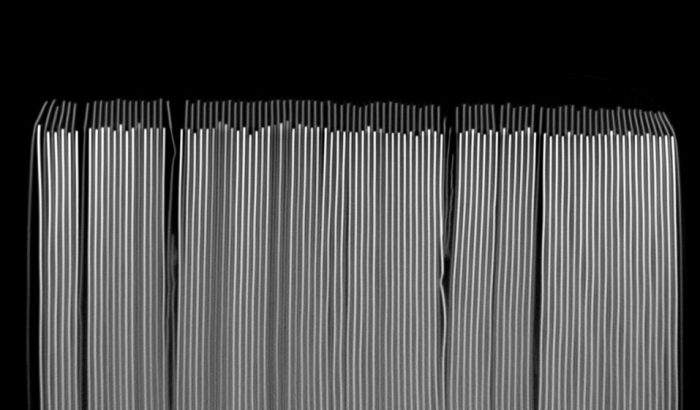

Additive Manufacturing

Our industrial CT machines are revolutionizing additive manufacturing quality assurance. We provide non-destructive, high-resolution 3D imaging for safety-critical parts in medical, aerospace, and automotive industries. Our technology precisely measures dimensions and detects internal defects, ensuring printed components meet the highest standards.

By enabling comprehensive analysis of complex geometries and hidden features, we’re driving innovation in 3D printing quality control. Manufacturers can now produce reliable, high-performance parts for critical applications with confidence.

Unveiling the unseen, we’re printing the future – layer by perfect layer.

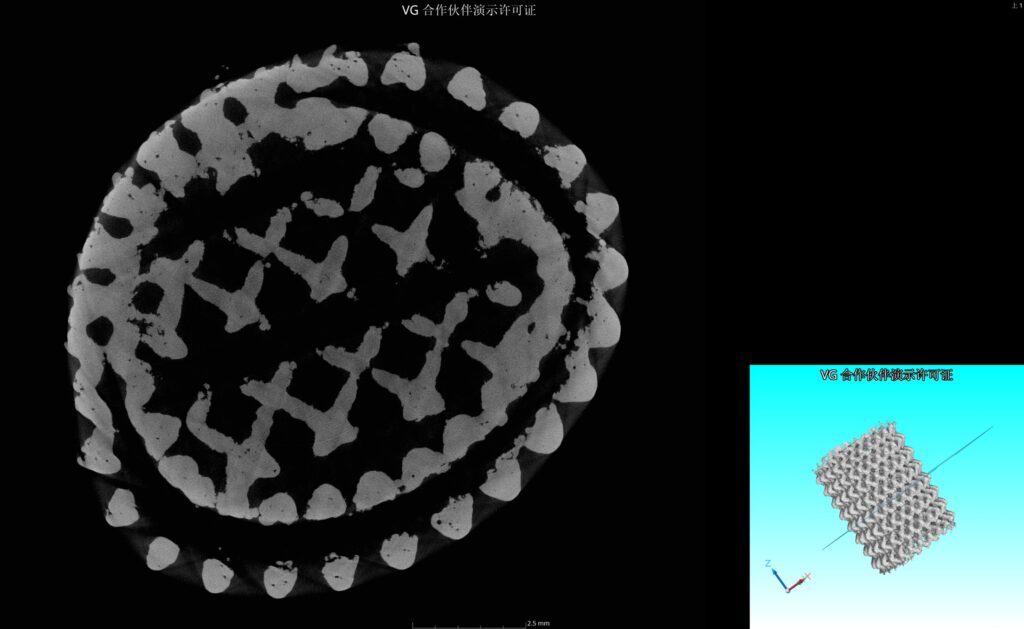

Battery industry

At the cutting edge of battery innovation, our industrial CT machines revolutionize quality assurance in battery production. Our advanced technology provides non-destructive, high-resolution 3D imaging that detects critical defects like electrode overhangs, welding imperfections, and foreign particles.

From research laboratories to production lines, our scanners help prevent battery shortcuts and potential fires by enabling comprehensive structural analysis. As the electric vehicle market expands, our CT solutions ensure battery safety, reliability, and performance, driving technological advancement in this critical industry.

We don’t just inspect batteries – we safeguard their future.